Tel: 13807296531

0712-5259111

Fax: 0712-5259166

E-mail: hbanliang@126.com

Post Code: 432600

Address: No. 66 Jiefang Avenue East Road, Anlu City, Hubei Province

Tel: 13807296531

0712-5259111

Fax: 0712-5259166

E-mail: hbanliang@126.com

Post Code: 432600

Address: No. 66 Jiefang Avenue East Road, Anlu City, Hubei Province

summary

This series of models for rice bran, soy and other low oil and pre-pancake in the solvent before leaching puffing treatment, is an ideal production process. Has become a domestic and foreign oil plant to save equipment investment, increase production, reduce energy consumption, improve product quality an important means.

working principle

The oil is squeezed, heated, sheared, rubbed and so on in the extrusion chamber of the extruder, and the direct steam is injected so that the material is fully mixed, cooked, gelled and gelatinized. 1.4 - 4.0MPa, the temperature of 110 - 120 degrees Celsius, in the expansion machine at the exit of the template suddenly reduced to normal temperature and pressure, rapid evaporation of water vapor, intracellular oil full exposure, resulting in numerous tiny pores and surface cracks in the expansion of materials The It is easier to leach the oil into the oil cells and oil from the cells due to the puffing effect, which improves the leaching and desolvation efficiency. Also increased the material bulk density of about 30%, thus improving the processing capacity of leaching equipment. As the material in the expansion machine to stay a short time (less than 30 seconds), less effective components damage to the quality of raw materials to protect the benefit.

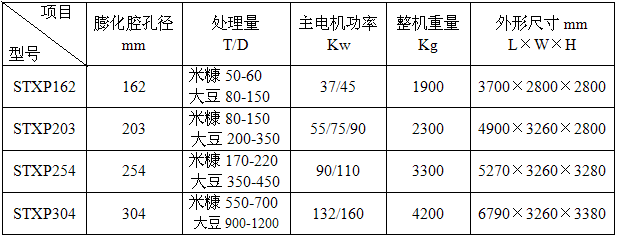

Technical data